- Главная

- Категории

- Деревообработка

- Jointing technology

- Ultra/Ultra TT 1000

WEINIG

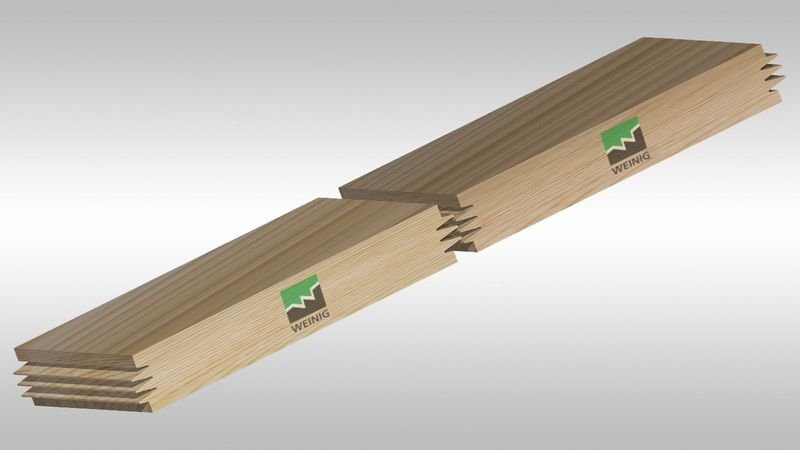

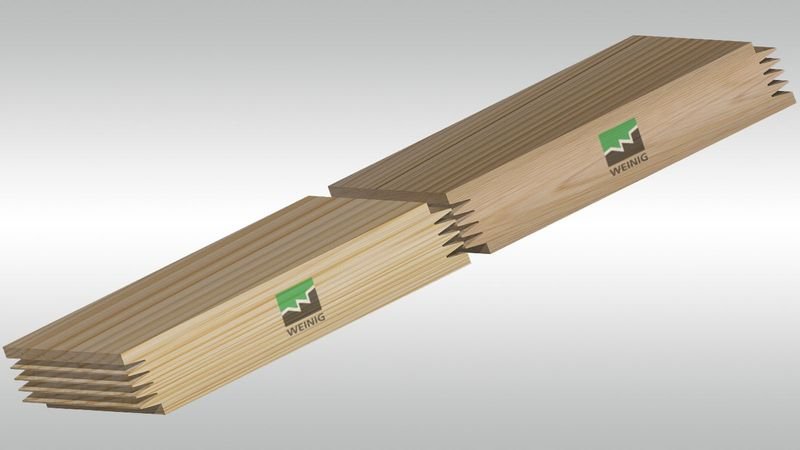

Ultra/Ultra TT 1000

Jointing technology

The compact Ultra offers all the benefits of advanced WEINIG technology, high performance and ample flexibility. With a manually or automatically operated turntable running along the line, this is the perfect solution for commercial use of residue wood in medium-sized businesses. The standard dimensions for this production line are as follows: wood widths of 205 mm and raw wood lengths of 150 to 1,000 mm. However, it can also process wood entry lengths of 1,500 mm. By increasing the press force to 145 kN (14.5 t), even large cross-sections can be processed securely and accurately.

WEINIG finger jointing line for short timber pieces offers you

- Finger joint profiles for all areas of use

- Maximum precision and stability of finger joints

- Robust and powerful

- High operational capacity, up to 200 pieces/min (28 km/8h-shiftr)

- Convenient and user-friendly

- Processing with one and two component glue

- Compact and efficient production process

- Statistics and production data recording

- Customized level of automation - from manual to fully automatic

- Expandable using peripheries, such as feeding systems and stacking systems

WEINIG Ultra/Ultra TT 1000 offers you

- Frequency or servo-controlled shaper table feed

- Infeed length up to 1,000 mm (optional also up to 1,500 mm)

- Semiautomatic to fully automatic system configuration possible

- Shaper heights up to 205 mm (optional also 225 mm)

- Performance doubling from Ultra to Ultra TT

- Membrane glue pump for all one-component glues

- Glue amount and glue application monitoring (optional)

- Vibration stop, package adjustment monitoring and splinter protection for improved quality

- Maintenance-free WEINIG shaper spindle with hub function

- Statistics and diagnosis function, using touch panel

| Ultra | Ultra comfort | Ultra performance | |

| Wood entry length | 150 - 1,000 mm | 150 - 1,000 mm | 150 - 1,000 mm |

| Wood width | 40 - 205 (225) mm | 40 - 205 (225) mm | 40 - 205 (225) mm |

| Wood thickness | 20 - 80 mm | 20 - 80 mm | 20 - 80 mm |

| Wood exit length | 3,000 - 6,100 mm | 3,000 - 6,100 mm | 3,000 - 6,100 mm |

| Press force | 120 (145) kN | 120 (145) kN | 120 (145) kN |

| Max. Timber cross section with a finger joint length of 10/11 mm (softwood) | 100 (120) cm² | 100 (120) cm² | 100 (120) cm² |

| Max. Timber cross section with a finger joint length of 10/11 mm (hardwood) | 80 (96) cm² | 80 (96) cm² | 80 (96) cm² |

| Performance (vertical finger joint) with 30 mm x 90 mm x 400 mm | 15.2 m/min. | 15.2 m/min. | 15.2 m/min. |

| Performance (horizontal finger joint) with 22 mm x 50 mm x 350 mm | 6.6 m/min. | 6.6 m/min. | 6.6 m/min. |

| Type of feeding system | Manual turntable | Manual turntable | Manual turntable |

| Type of shaper | Package individual shaper | Package individual shaper | Package individual shaper |

| Type of separation | Semiautomatic | Semiautomatic | Automatic |

| Type of press | Two-channel press | Two-channel press | Two-channel press |

| Statistics function | Standard | Standard | Standard |

| Diagnostic system | Standard | Standard | Standard |

| Multiple lengths | Option | Standard | Standard |

| Number of intermediate steps | 5 | Infinity | Infinity |

| Avoiding splintering in wood (scoring unit) | Option | Option | Option |

| Min. wood thickness 16 mm | Option | Option | Option |

| Max. wood thickness 72 mm | - | - | - |

| Max. wood thickness 100 mm | Option | Option | Option |

| Min. wood width 30 mm | Option | Option | Option |

| Vibration stop | Option | Option | Standard |

| Wood adjustment monitoring | Option | Option | Standard |

| Quality monitoring | - | - | - |

| Splinter protection | Standard | Standard | Standard |

| FlankenJet glue comb | Standard | Standard | Standard |

| Communications (Teleservice) | Option | Option | Option |

| Performance reserves cutting spindle | Option | Option | Option |

| Frequency-controlled feed type | Standard | Standard | Standard |

| Servo-controlled feed type | - | - | - |

| Drive performance - cutting spindle | 22 (37) kW | 22 (37) kW | 22 (37) kW |

| Drive performance - hogger (+ scoring unit) | 11.5 kW | 11.5 kW | 11.5 kW |