- Главная

- Категории

- Деревообработка

- Jointing technology

- PowerJoint

WEINIG

PowerJoint

Jointing technology

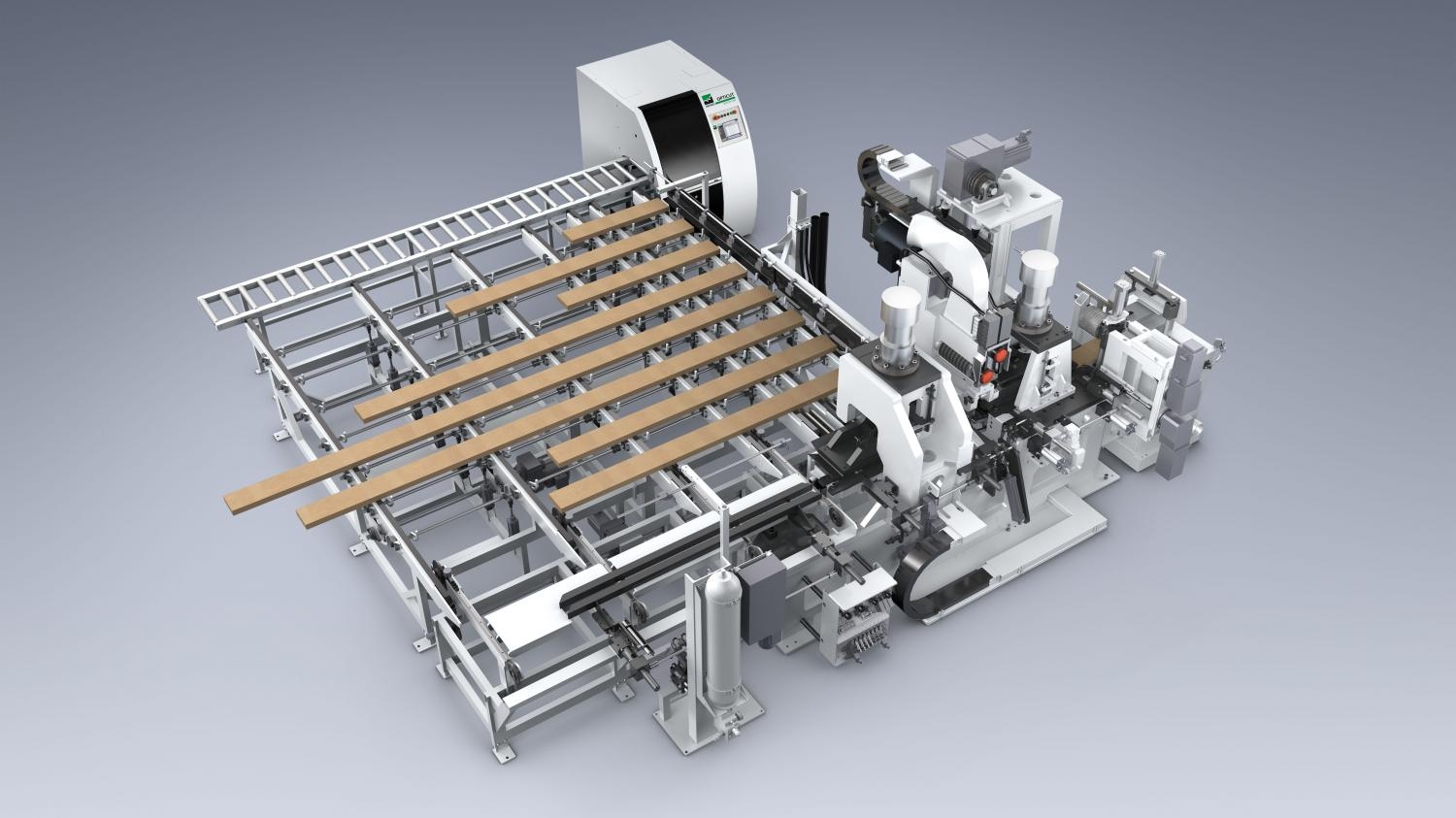

1. PJ - 6 cycles/min.

The PowerJoint is a compact line with contact-free glue application. Shaping is done from top to bottom, which guarantees the best finger joint quality. Transporting the “freshly” pressed finger joints only occurs in the production direction, which means that the load application on the joint is lower. Another benefit is that the timbers pass through the middle of the line. This means that there is a very good distribution of thrust force and the best use of tools.

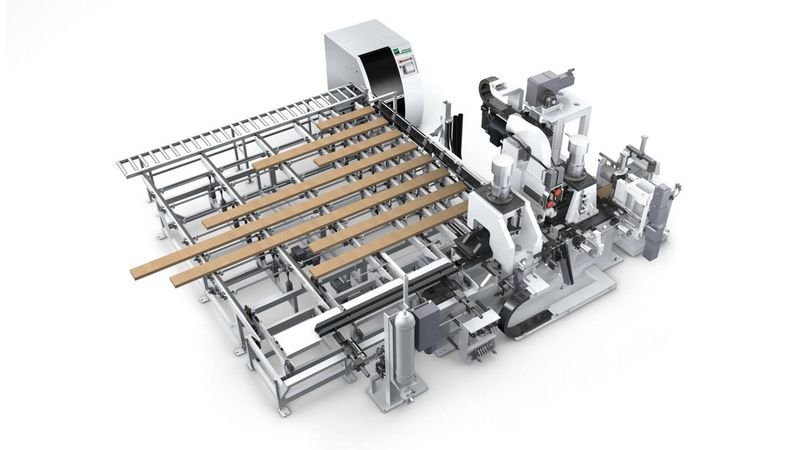

2. PJ - 8 cycles/min.

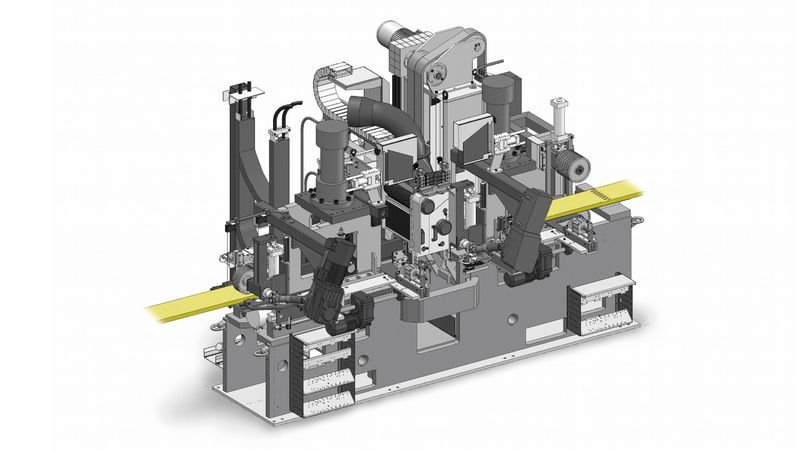

The PowerJoint 8 is the fastest line in the compact construction style (shaping/gluing/pressing in one clamping process). The increase in performance is achieved by feeding the line from the side. The timbers are immediately clamped in a central position and then pass through the shaping, contact-free gluing and pressing. The scoring unit, shaping spindles and the glue nozzles for contact-free gluing are integrated into the shaper head. PowerJoint-8_Fräskopf_16_9.jpg

2. PJ - 15 cycles/min.

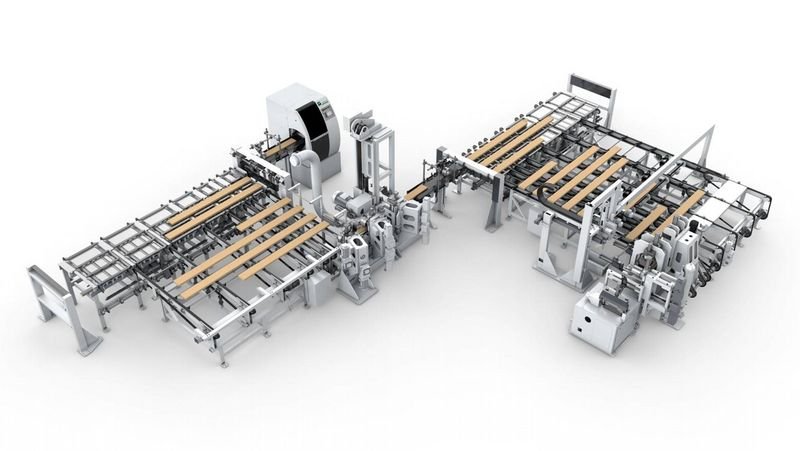

The ultimate increase in capacity can be achieved using the PowerJoint family by separating the shaper unit from the gluing and the press. In this way a PowerJoint with up to 15 joints/min can be obtained. With the individual components working simultaneously an increase in capacity of almost 100% compared to PowerJoint 8 is possible.

We have also integrated the benefits of PowerJoint here, for example, conveying the work pieces only in the output direction (no reverse positioning), indirect gluing and production of an endless phase.

WEINIG compact lines offer you

- Very compact construction of different lines

- Pressing force of 20, 30 or even 40 tonnes

- Capacities of 3.5 up to 15 joints/min possible

- Optionally available with additional sound insulation cabinet

- Production of an endless phase

- With splinter protection to avoid splintering in the timber

- Glue comb systems or contact-free glue application

WEINIG PowerJoint offers you

- Vertical finger joint including scoring unit to avoid splintering

- Shaping process from top to bottom (defined work piece support)

- No reverse positioning of the timbers (no load on the finger joints)

- Contact-free glue application using glue nozzles

- Servo-controlled drive profile of the shaper head for fantastic shaping result

- Statistics and diagnosis system using touch panel

- Short wood entry lengths from 700 mm possible