- Главная

- Категории

- Деревообработка

- Jointing technology

- Turbo-S 2000-4000

WEINIG

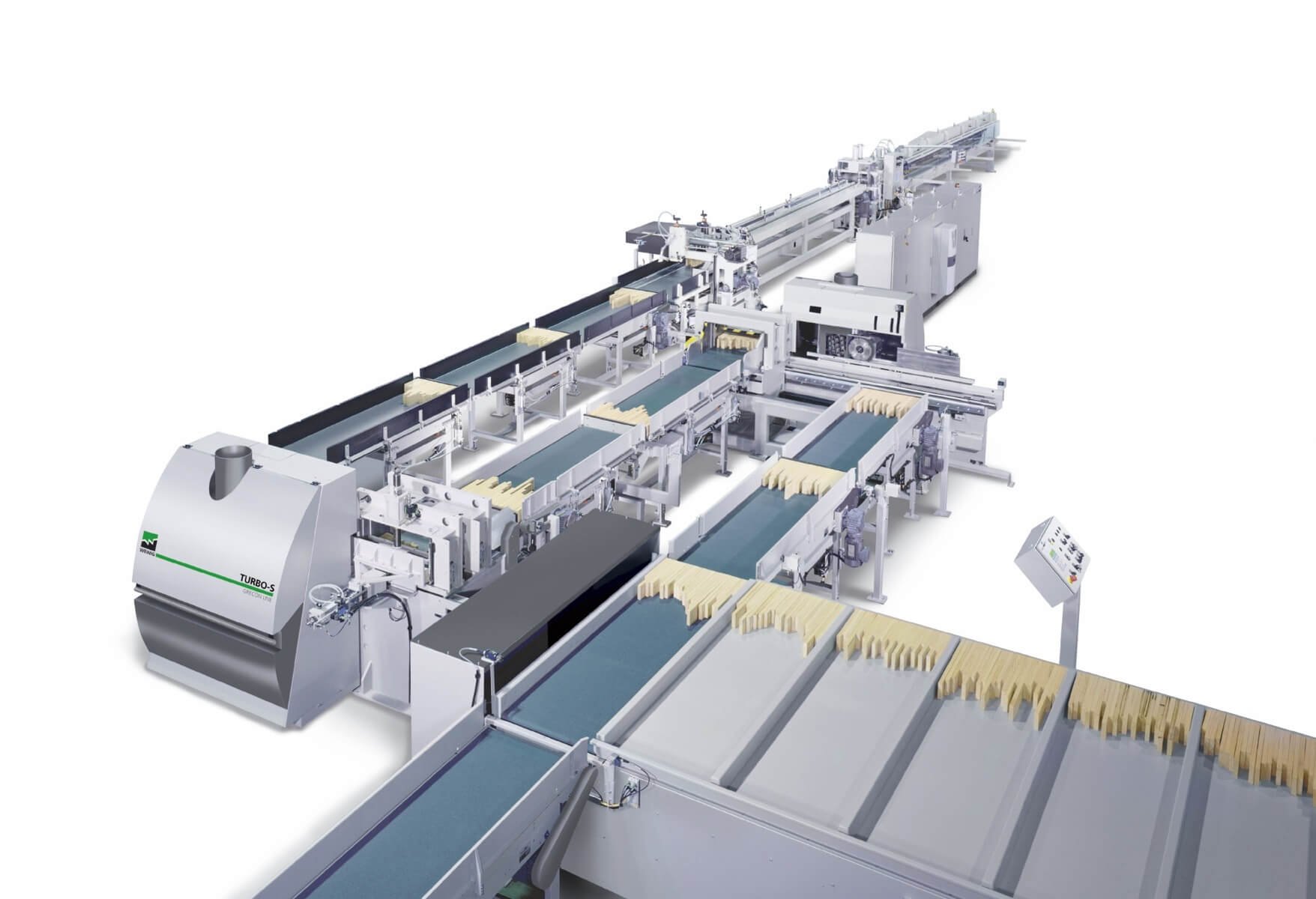

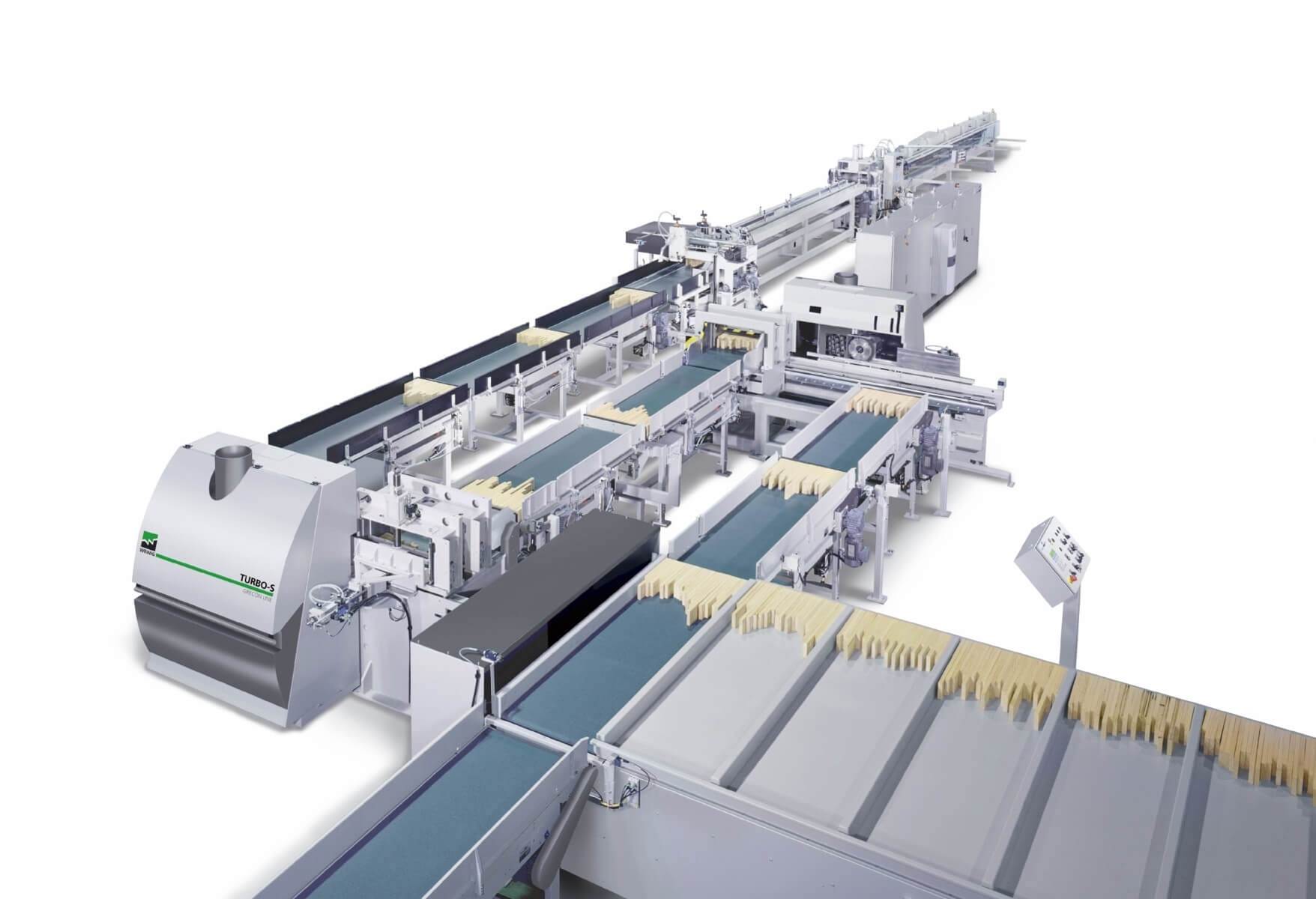

Turbo-S 2000-4000

Jointing technology

1. Turbo-S 2000

Turbo-S 2000 is a double shaper for a package width of up to 600 mm, a package height (lamella width) of up to 225 mm and a package length of 200 - 2,000 mm. The patented turbo effect is achieved using independent shaping processes from shaper 1 and shaper 2. Continuous feeding systems provide the transfer to the various press units. The average capacity of the shaper is between 5.5 packages/min and a maximum of 7.5 packages/min.

2. Turbo-S 3000/4000

This double shaper is constructed for a package width of up to 600 mm, a package height (lamella width) of up to 225 mm and a package length of 200 - 3,000/4,000 mm. The shaper combination produces on average 3.5 packages/min. Press systems can be combined as desired for all end lengths.

WEINIG construction timber lines offer you

- Vertical and horizontal jointing is possible

- Long wood entry length such as 2 m, 3 m, 4 m or even 6 m

- Shaper heights (timber width) up to 300 mm

- Almost all glue types possible

- Front-end, extrusion, cycle or through-feed presses possible

- Vibration stop, package adjustment monitoring and splinter protection

- Semiautomatic electrical adjustment

WEINIG Turbo-S 2000-4000 offers you

- Patented shaper combination for high capacities

- Vertical and also horizontal jointing is possible

- Long wood entry lengths of 2, 3 and 4 m

- Short wood entry lengths of up to 200 mm

- One-sided or double-sided glue application

- Timber widths (shaper heights) up to 225 mm

- Almost all glue types can be used

- Measurement of glue volumes for one-component glues (PVAC and PU)

- All press types can be used (cycle, extrusion and front-end presses)

- Teleservice (remote maintenance)

| Turbo-S 2000 | Turbo-S 3000 | Turbo-S 4000 | |

| Wood entry length | 200 - 2,000 mm | 200 - 3,000 mm | 200 - 4,000 mm |

| Wood width | 40 - 205 (225) mm | 40 - 205 (225) mm | 40 - 205 (225) mm |

| Wood thickness | 20 - 80 mm | 20 - 80 mm | 20 - 80 mm |

| Wood exit length | 3,000 - 6,100 mm | 3,000 - 6,100 mm | 3,000 - 6,100 mm |

| Press force | 120 (145) kN | 120 (145) kN | 120 (145) kN |

| Max. Timber cross section with a finger joint length of 10/11 mm (softwood) | 100 (120) cm² | 100 (120) cm² | 100 (120) cm² |

| Max. Timber cross section with a finger joint length of 10/11 mm (hardwood) | 80 (96) cm² | 80 (96) cm² | 80 (96) cm² |

| Performance (vertical finger joint) with 30 mm x 90 mm x 1,500 mm | 70 m/min | 70 m/min | 70 m/min |

| Performance (horizontal finger joint) with 22 mm x 50 mm x 750 mm | 48.4 m/min. | 39.6 m/min. | 30.8 m/min. |

| Type of feeding system | Feeding line/fan feed | Fan feed | Fan feed |

| Type of shaper | Package shaper combination | Package shaper combination | Package shaper combination |

| Type of separation | Automatic | Automatic | Automatic |

| Type of press | Two-channel press | Two-channel press | Two-channel press |

| Statistics function | Standard | Standard | Standard |

| Diagnostic system | Standard | Standard | Standard |

| Multiple lengths | Standard | Standard | Standard |

| Number of intermediate steps | infinity | infinity | infinity |

| Avoiding splintering in wood (scoring unit) | Option | Option | Option |

| Min. wood thickness 16 mm | Option | Option | Option |

| Max. wood thickness 72 mm | - | - | - |

| Max. wood thickness 100 mm | Option | Option | Option |

| Min. wood width 30 mm | Standard | Standard | Standard |

| Vibration stop | Standard | Standard | Standard |

| Wood adjustment monitoring | Standard | Standard | Standard |

| Quality monitoring | - | - | - |

| Splinter protection | Standard | Standard | Standard |

| FlankenJet glue comb | Standard | Standard | Standard |

| Communications (Teleservice) | Option | Option | Option |

| Performance reserves cutting spindle | Option | Option | Option |

| Frequency-controlled feed type | Standard | Standard | Standard |

| Servo-controlled feed type | Option | Option | Option |

| Drive performance - cutting spindle | 22 (37) kW | 22 (37) kW | 22 (37) kW |

| Drive performance - hogger (+ scoring unit) | 11.5 kW | 11.5 kW | 11.5 kW |