- Главная

- Категории

- Деревообработка

- Jointing technology

- FL 200/300

WEINIG

FL 200/300

Jointing technology

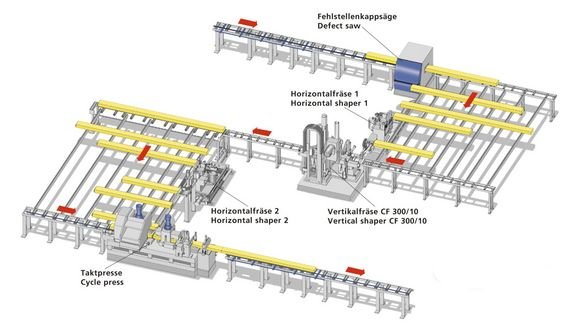

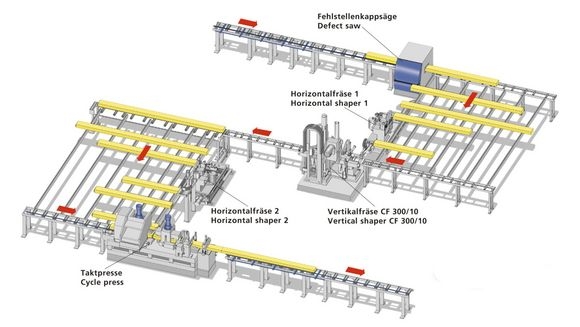

The VS 200 / 300 has two vertical single timber shapers that face each other in an offset position. This finger jointing line processes each work piece very precisely - shaping a vertical finger joint. This is possible as a result of a continuous chain installed between the shapes.

Following the shaping unit, the work pieces are then conveyed through a cross feeder transfer into the feed in track and from there into the press. When making your selection, your can also choose our new through-feed press. However, other solutions are available.

The precise positioning of the work piece onto the shaping unit produces a very high quality end product and this occurs at high speed.

В серии HS 2000–6000 есть дополнительные линии для горизонтальных швов, а в VS 5000 – для вертикальных швов.

WEINIG single panel lines offer you

- Every work piece is individually aligned and processed.

- High-performance lines for capacities up to 180 (200) m/min.

- With automatic feeding system and stacking solutions

WEINIG VS 200 / 300 offers you

- High quality: Each lamella is individually aligned and clamped on four sides

- Material yield: Short infeed lengths can be processed

- Flexible length range: VS 200: 300-3200 mm / 150 pieces, VS 300: 600-6200 mm / 70 pieces

- Shaper capacity: up to 150 pieces / min

- Capacity of the press: up to 180 (200) m/min

WEINIG VS 200 / 300 offers you

- High quality: Each lamella is individually aligned and clamped on four sides

- Material yield: Short infeed lengths can be processed

- Flexible length range: VS 200: 300-3200 mm / 150 pieces, VS 300: 600-6200 mm / 70 pieces

- Shaper capacity: up to 150 pieces / min

- Capacity of the press: up to 180 (200) m/min