- Главная

- Категории

- Деревообработка

- Jointing technology

- HS 2000 - 6000

WEINIG

HS 2000 - 6000

Jointing technology

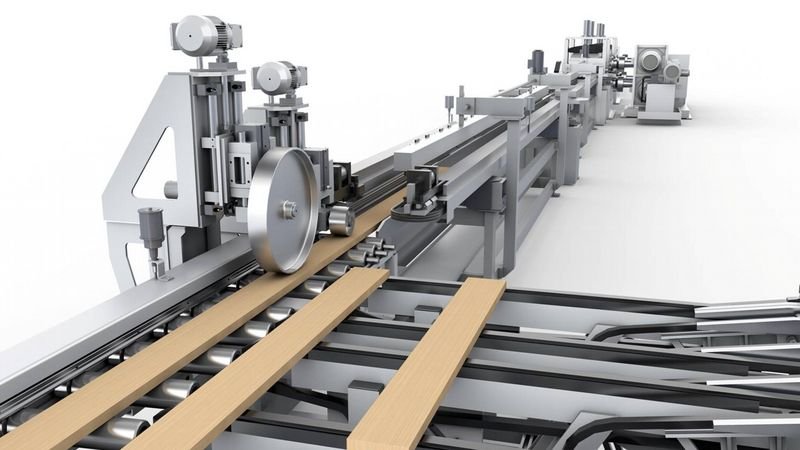

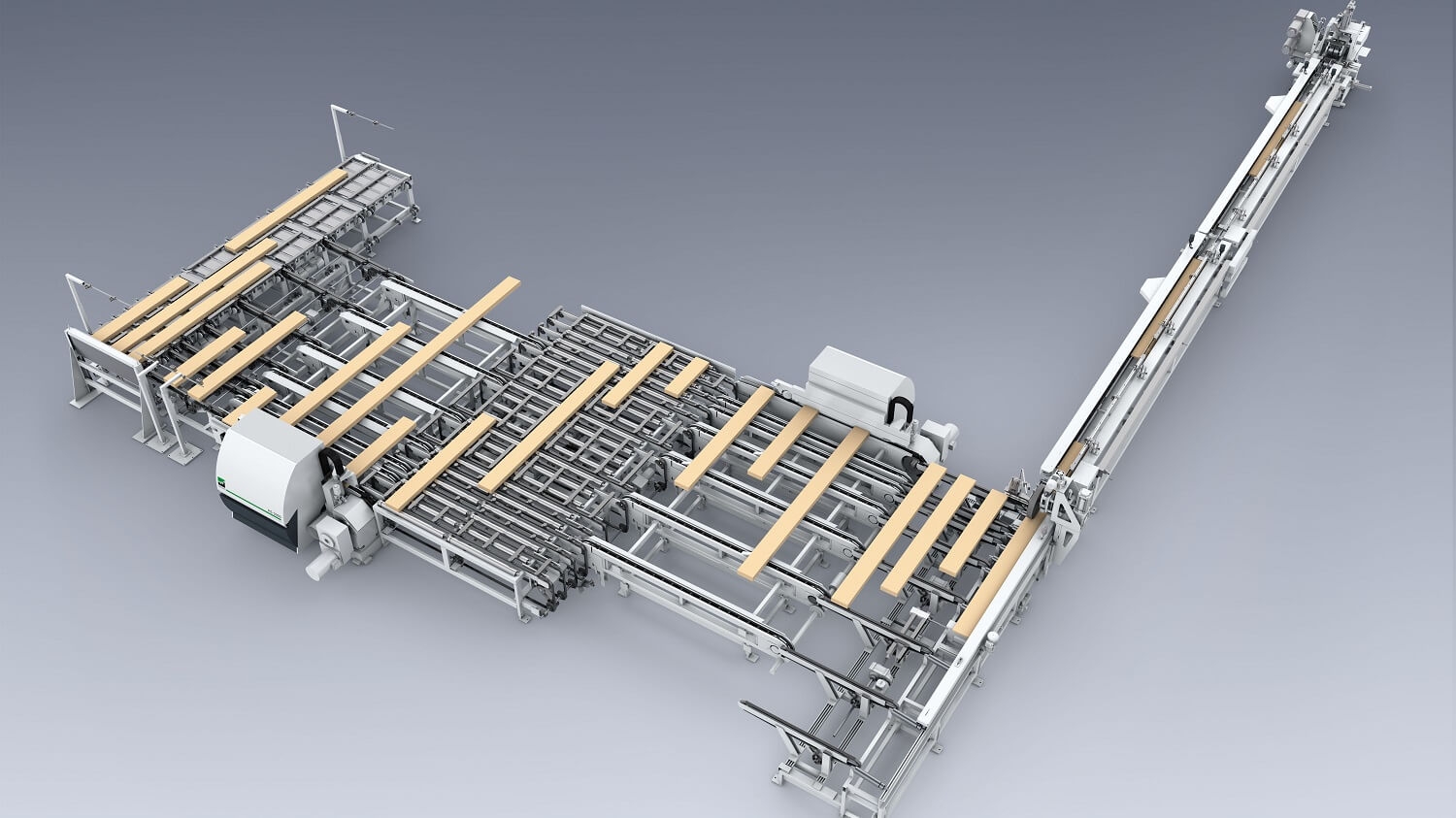

You can design your production very flexibly with the HS 2000 - 6000 series. Infeed lengths of up to 6 meters can be processed with HS. This means that the line reaches a shaping capacity of 80 parts/min.

A special timber adjustment in the shapers minimizes any possible curvature of the panels in order to produce a straighter end product.

This can be used, for example, in the production of timber house planks and plywood.

Your benefits: Very high quality end products - as a result of the modular construction of this generation of lines, the components of your finger jointing line are totally adjusted to your timber feed in products and the final goods.

WEINIG single panel lines offer you

- Every work piece is individually aligned and processed.

- High-performance lines for capacities up to 180 (200) m/min.

- With automa

WEINIG HS 2000 - 6000 offers you

- Material savings: No height offset for horizontal joints

- Flexibility Short and long timbers can be processed after each other

- All current types of glue can be used.

- Possible to use front-end, cycle, extrusion and through-feed presses

- Scoring units above and below enable every horizontal profile.

- Automatic centering of the panel curve (straight end product)

- Indirectly driven tools using proven Weinig spindles

- Gentle feed-in before the press (no damaged joints, lower cleaning costs)