- Главная

- Категории

- Деревообработка

- Jointing technology

- Turbo-S 1000

WEINIG

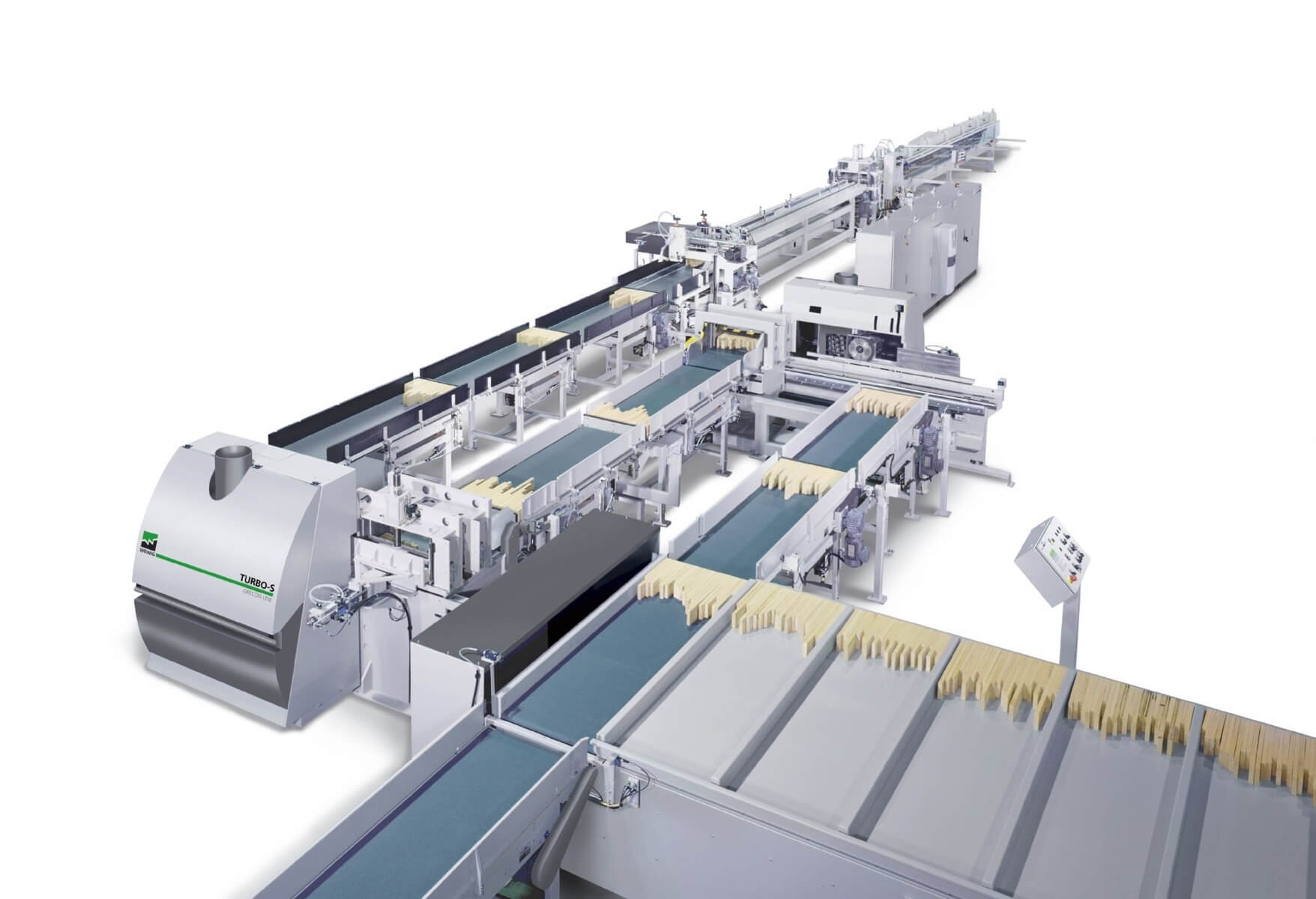

Turbo-S 1000

Jointing technology

The patented shaper combination of the Turbo-S 1000 meets all your performance and quality needs. Two shapers connected by an intermediary belt work independently, offering top quality performance.

The modular design means the production line can be set up according to customer requirements. The system offers a variety of benefits including quality standards such as package monitoring, splinter protection and pre-scorers.

WEINIG finger jointing line for short timber pieces offers you

- Finger joint profiles for all areas of use

- Maximum precision and stability of finger joints

- Robust and powerful

- High operational capacity, up to 200 pieces/min (28 km/8h-shiftr)

- Convenient and user-friendly

- Processing with one and two component glue

- Compact and efficient production process

- Statistics and production data recording

- Customized level of automation - from manual to fully automatic

- Expandable using peripheries, such as feeding systems and stacking systems

WEINIG Turbo-S 1000 offers you

- Servo drive for the shaper table feed

- Fully automatic system for the higher performance area

- Shaper combination with many buffer places for highest performance

- Universal system for all types of finger joint

- Almost all types of glue can be used

- Glue amount and glue application monitoring (optional)

- Maximum performance up to 150 parts/min can be processed

- Press performance for front-end press up to 12 cycles per minute

- Operation, statistics and diagnostics function using touch panel

- Inclusive teleservice (remote maintenance) for improved customer support

| Turbo-S 1000 | Turbo-S 1000 performance | |

| Wood entry length | 150 - 1,000 mm | 150 - 1,000 mm |

| Wood width | 40 - 205 (225) mm | 40 - 205 (225) mm |

| Wood thickness | 20 - 80 mm | 20 - 80 mm |

| Wood exit length | 3,000 - 6,100 mm | 3,000 - 6,100 mm |

| Press force | 120 (145) kN | 120 (145) kN |

| Max. Timber cross section with a finger joint length of 10/11 mm (softwood) | 100 (120) cm² | 100 (120) cm² |

| Max. Timber cross section with a finger joint length of 10/11 mm (hardwood) | 80 (96) cm² | 80 (96) cm² |

| Performance (vertical finger joint) with 30 mm x 90 mm x 400 mm | 46.04 m/min. | 57.56 m/min. |

| Performance (horizontal finger joint) with 22 mm x 50 mm x 350 mm | 25.69 m/min. | 27.53 m/min. |

| Type of feeding system | Feeding line/fan feed | Fan feed |

| Type of shaper | Package shaper combination | Package shaper combination |

| Type of separation | Automatic | Automatic |

| Type of press | Two-channel press | Two-channel press |

| Statistics function | Standard | Standard |

| Diagnostic system | Standard | Standard |

| Multiple lengths | Standard | Standard |

| Number of intermediate steps | Infinity | Infinity |

| Avoiding splintering in wood (scoring unit) | Option | Option |

| Min. wood thickness 16 mm | Option | Option |

| Max. wood thickness 72 mm | - | - |

| Max. wood thickness 100 mm | Option | Option |

| Min. wood width 30 mm | Standard | Standard |

| Vibration stop | Standard | Standard |

| Wood adjustment monitoring | Standard | Standard |

| Quality monitoring | - | - |

| Splinter protection | Standard | Standard |

| FlankenJet glue comb | Standard | Standard |

| Communications (Teleservice) | Option | Option |

| Performance reserves cutting spindle | Option | Option |

| Frequency-controlled feed type | Standard | - |

| Servo-controlled feed type | Option | Standard |

| Drive performance - cutting spindle | 22 (37) kW | 22 (37) kW |

| Drive performance - hogger (+ scoring unit) | 11.5 kW | 11.5 kW |