- Главная

- Категории

- Деревообработка

- Jointing technology

- Ultra TT 2000-4000

WEINIG

Ultra TT 2000-4000

Jointing technology

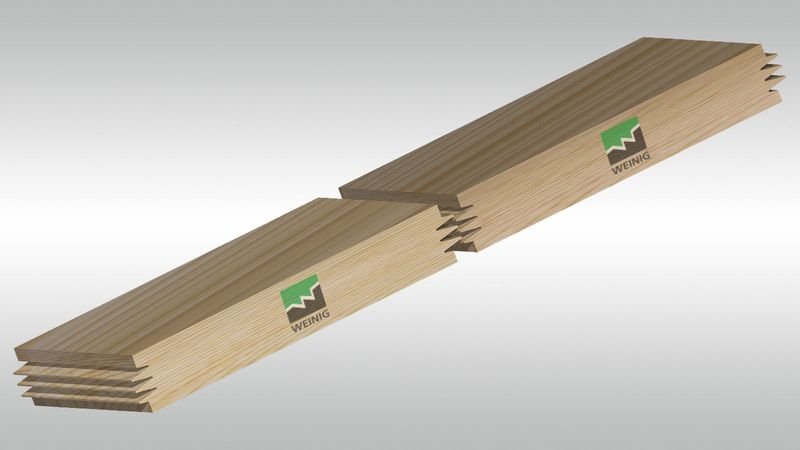

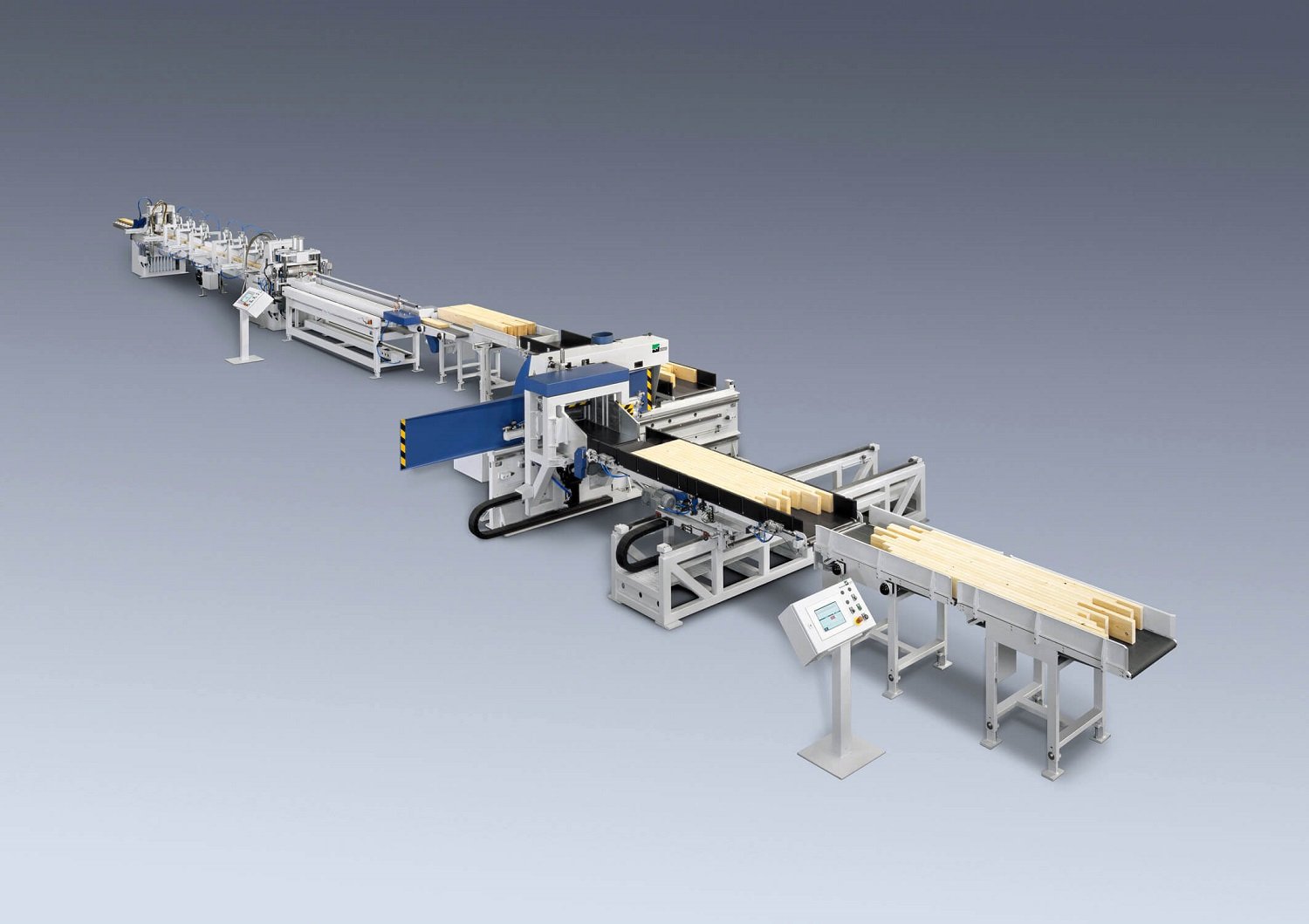

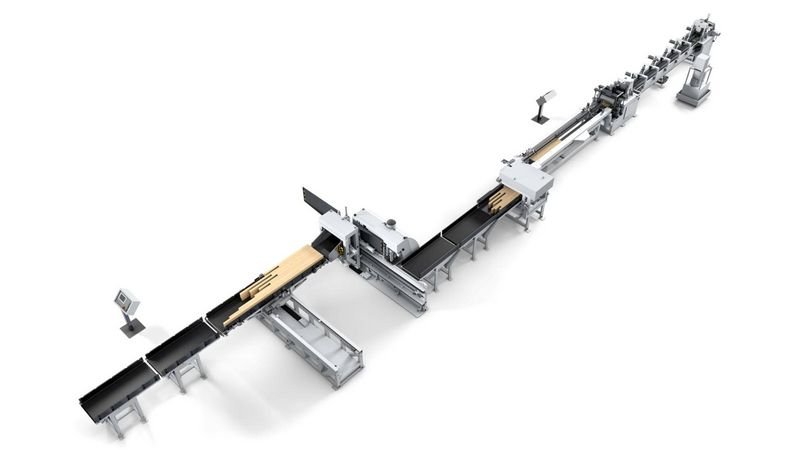

The Ultra TT 2000/3000/4000 is mainly used to produce construction timber elements.

The individual shaper is designed to a package width of 600 mm, a package height (lamella width) of 280 mm and a package length of 300 - 2,000 (3,000 or 4,000) mm. Shaping and glue application on the second side is carried out after a turn of 180° on an automatic, traveling servo-turntable. Almost all types of glue can be used.

The pressing process is carried out as an endless length with an extrusion press or as a fixed length using various front-end presses (6/7.2/9.3/12/16/18 m). The average capacity is around two packages/min.

WEINIG construction timber lines offer you

- Vertical and horizontal jointing is possible

- Long wood entry length such as 2 m, 3 m, 4 m or even 6 m

- Shaper heights (timber width) up to 300 mm

- Almost all glue types possible

- Front-end, extrusion, cycle or through-feed presses possible

- Vibration stop, package adjustment monitoring and splinter protection

- Semiautomatic electrical adjustment

WEINIG Ultra TT 2000-4000 offers you

- Servo-driven automatic turntable

- Maximum wood entry length of 2 m, 3 m or even 4 m

- Shaper heights (timber width) up to 280 mm

- Shaper body is very heavy design

- Double tensioning station on the shaping unit

- Vertical and even horizontal profile possible

- One-sided or even double-sided glue application using individual shaper

- Up to 50 kW shaper spindle drive for maximum speed

- Shortest wood entry length is 300 mm

- Semiautomatic and fully automatic system

| Ultra TT 2000 | Ultra TT 3000 | Ultra TT 4000 | |

| Wood entry length | 300 - 2,000 mm | 300 - 3,000 mm | 300 - 4,000 mm |

| Wood width | 40 - 205 (300) mm | 40 - 205 (300) mm | 40 - 205 (300) mm |

| Wood thickness | 20 - 80 mm | 20 - 80 mm | 20 - 80 mm |

| Wood exit length | 3,000 - 6,100 mm | 3,000 - 6,100 mm | 3,000 - 6,100 mm |

| Press force | 120 (145, 160) kN | 120 (145, 160) kN | 120 (145, 160) kN |

| Max. Timber cross section with a finger joint length of 10/11 mm (softwood) | 100 (120, 133) cm² | 100 (120, 133) cm² | 100 (120, 133) cm² |

| Max. Timber cross section with a finger joint length of 10/11 mm (hardwood) | 80 (96, 106) cm² | 80 (96, 106) cm² | 80 (96, 106) cm² |

| Performance (vertical finger joint) with 30 mm x 90 mm x 1,500 mm | 51.3 m/min. | 51.3 m/min. | 51.3 m/min. |

| Performance (horizontal finger joint) with 22 mm x 50 mm x 750 mm | 14.9 m/min. | 14.9 m/min. | 14.9 m/min. |

| Type of feeding system | Feeding line/fan feed | Fan feed | Fan feed |

| Type of shaper | Package individual shaper | Package individual shaper | Package individual shaper |

| Type of separation | Semi/automatic | Semi/automatic | Semi/automatic |

| Type of press | Two-channel press | Two-channel press | Two-channel press |

| Statistics function | Standard | Standard | Standard |

| Diagnostic system | Standard | Standard | Standard |

| Multiple lengths | Standard | Standard | Standard |

| Number of intermediate steps | infinity | infinity | infinity |

| Avoiding splintering in wood (scoring unit) | Option | Option | Option |

| Min. wood thickness 16 mm | Option | Option | Option |

| Max. wood thickness 72 mm | - | - | - |

| Max. wood thickness 100 mm | Option | Option | Option |

| Min. wood width 30 mm | Option | Option | Option |

| Vibration stop | Standard | Standard | Standard |

| Wood adjustment monitoring | Standard | Standard | Standard |

| Quality monitoring | - | - | - |

| Splinter protection | Standard | Standard | Standard |

| FlankenJet glue comb | Standard | Standard | Standard |

| Communications (Teleservice) | Option | Option | Option |

| Performance reserves cutting spindle | Option | Option | Option |

| Frequency-controlled feed type | - | - | - |

| Servo-controlled feed type | Standard | Standard | Standard |

| Drive performance - cutting spindle | 22 (37, 50) kW | 22 (37, 50) kW | 22 (37, 50) kW |

| Drive performance - hogger (+ scoring unit) | 11.5 (15) kW | 11.5 (15) kW | 11.5 (15) kW |