- Главная

- Категории

- Деревообработка

- Windows CNC Technology

- Сonturex Vario S & L

WEINIG

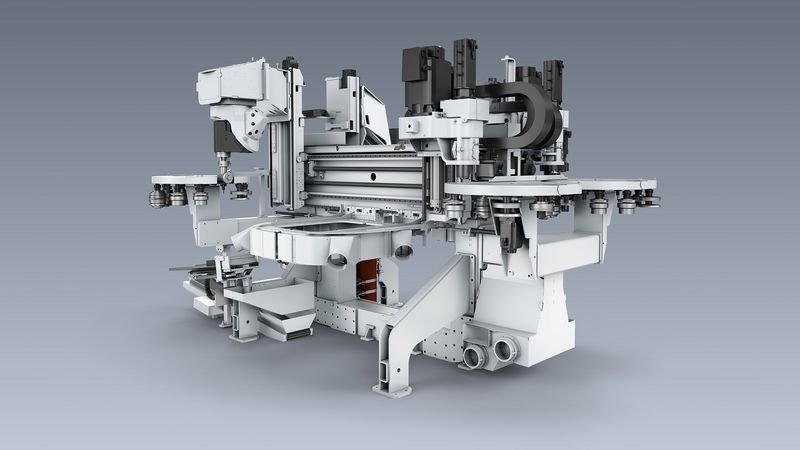

Сonturex Vario S & L

Greater flexibility in woodworking

The WEINIG Conturex is one of the most flexible and high-output CNC processing centers owned by window manufacturers worldwide.

Thanks to the new combination of variable single clamping tables, the system will be fully compatible with double parts. This means a significant minimization of tool changing times. At the same time, the load on the entire system is significantly less. The required flexibility of current window and door systems was also taken into account in process optimization.

These days, the window and furniture production market is characterized by challenging custom solutions. But if high throughput is also required, then Conturex Vario S is the answer. One particularly special feature of this fully automated WEINIG powerhouse is the PowerGrip Motion 2D/3D folding clamping system. It provides significantly more flexibility, especially when producing narrow profile systems and round arches, as well as when doing partial milling for system construction.

WEINIG CAM, WEINIG SIM and WEINIG Solid WF are the perfect software modules for programming, simulating and monitoring workpieces. The fact that the Conturex Vario S allows direct part transfer guarantees the highest workpiece quality. The new working width of up to 330 mm means that everything is covered, even for future products. Thanks to the 4-table process, output is significantly increased, especially for short parts. A 2 x 24-slot pick-up holder and an external magazine with 90 slots are available in the tool area. The machine’s enormous productivity is enhanced by the fact that even the smallest batch sizes can be processed with no set-up time. The new machine housing with improved visibility and accessibility, ensuring improved safety and ergonomic operation for machine operators, is also a highlight.

The WEINIG Conturex series offers you

- Complete processing in one clamping process

- Processing without processing times even for small lot sizes

- Automation enables less manpower in production

- Maximum flexibility as a result of the large tool magazine

- PowerGrip Motion 2D/3D

- New machine cabin with improved visibility and accessibility for service and maintenance

- Thinking in new dimensions – part widths up to 330 mm

- Advanced unit technology

- No limit to the corner joint possibilities