- Главная

- Категории

- Деревообработка

- Windows CNC Technology

- Conturex Vario XS

WEINIG

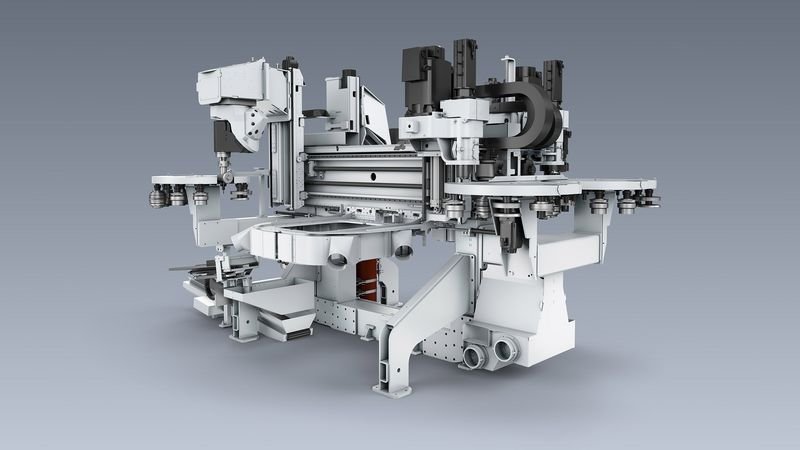

Conturex Vario XS

Greater flexibility in woodworking

With the Vario XS, the smallest of our CNC machining centers, not only industrial companies but also workshop businesses can now think in entirely new directions - from single-item batches to series production.

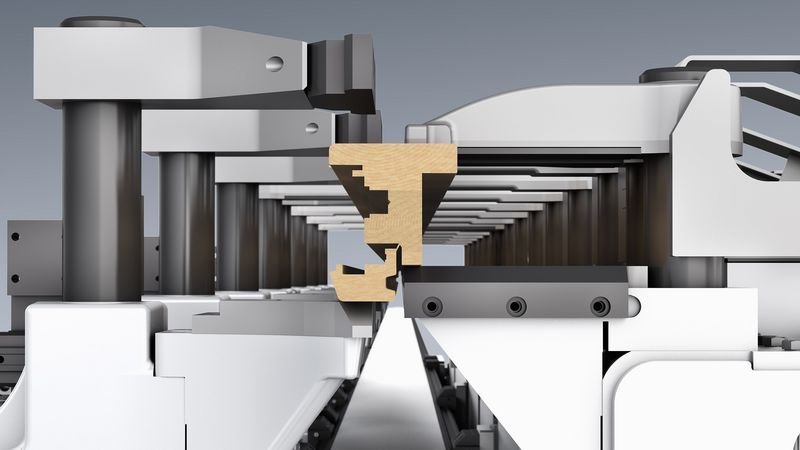

Thanks to the integration of the PowerGrip Motion 2D/3D clamping table, the Conturex Vario XS is in no way inferior to its big brothers S & L when it comes to CNC machining. The clamping table enables setup-free complete processing in a single clamping process and full freedom of movement in X, Y and Z directions. With the PowerGrip Motion 3D, workpieces of up to 330 mm, but also the smallest dimensions, can be clamped safely and processed flexibly.

The high degree of dimensional precision, profile accuracy and excellent surface quality of all workpieces speaks for itself. The patented clamping elements are programmed with the help of smart software solutions and individually controlled with the WMC (WEINIG MACHINE CONTROL) system.

The clearly laid out PC interface makes work much easier for the machine operator. Anyone who has experienced live how the patented WEINIG clamping technology of the Conturex Vario XS CNC machining center imitates the possible movements of the human hand will be impressed. For example, by the fast, direct and absolutely precise part transfer from table to table and by the way even narrow profiles are clamped securely in three dimensions. All of this is impressive indeed, but let’s not forget that the Conturex Vario XS has a lot more to offer.

The WEINIG Conturex series offers you

- Complete processing in one clamping process

- Processing without processing times even for small lot sizes

- Automation enables less manpower in production

- Maximum flexibility as a result of the large tool magazine

- Energy feedback modules means savings in energy

Thanks to the robust gantry design, the Conturex Vario XS can be equipped with heavy machines. Cast iron tracks provide a high level of dynamics. This CNC profiling center is mainly designed for complete processing of solid wood products.

The Conturex Vario XS offers a variety of equipment options that allow you to perfectly match it to your application. For example, you can use a universal spindle for the production of complex window profiles, a 5-axis head for absolute flexibility in the production of furniture, and multi-spindle drilling heads (MBK) for greater productivity when machining workpieces for fittings.