- Главная

- Категории

- Деревообработка

- Cutting / Gluing

- OptiCut 450 FJ+

WEINIG

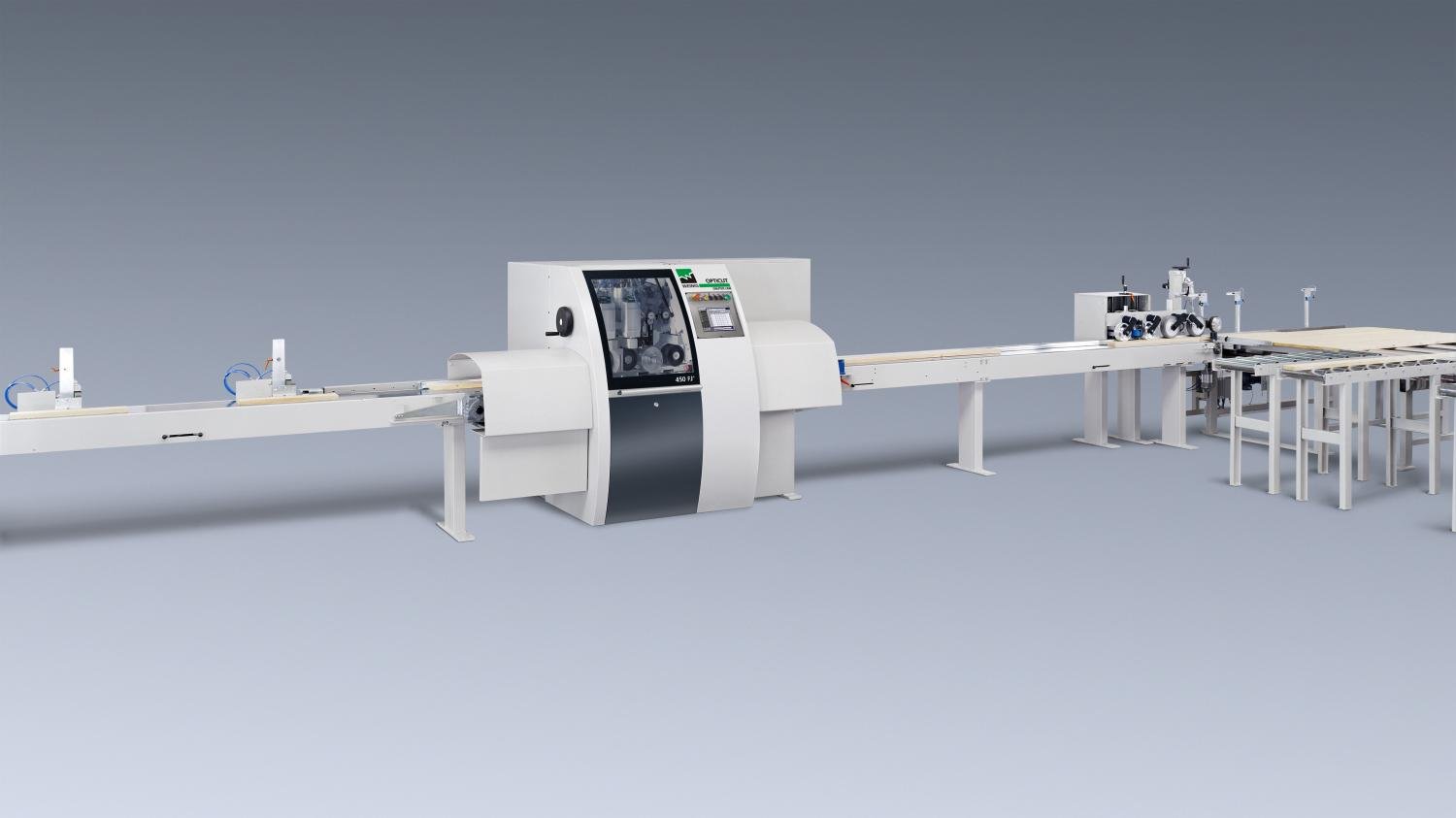

OptiCut 450 FJ+

Cutting / Gluing

The OptiCut 450 FJ+ is specially designed for finger jointing applications. The model variant code FJ stands for Finger Jointing. This variant features a special feed system that safely transports even the shortest OK parts. Thus, at the end of the board, the machine still retains full control over short parts up to 110 mm, which are reliably transferred to the sorting system.

In order to obtain the required output even with the shortest lengths, the OptiCut 450 FJ+ features the smart VarioSpeed infeed and the intelligently controlled high-performance waste gate even in the standard version. Individually suspended overhead feed rollers with HighGrip rollers, specially designed for the type of wood, apply full pressure to the workpieces for accurate positioning. To ensure exact positioning, the workpieces are completely measured in length even before the first saw cut. An additional non-driven measuring wheel in the saw ensures maximum cutting accuracy.

In addition to optional software solutions to optimize your production, various mechanization solutions are available. An OptiCut is constructed according to a modular system, which means that you are also well equipped for the future. You can react quickly to changing market requirements by adding appropriate extensions. Connecting scanners, OptiCut Stackers (for automatic stacking of preferred lengths) and/or extending the system to create multiple cross-cut lines are no problem.

The WEINIG OptiCut 450 FJ + provides

- Special machine concept for cutting short lengths

- Five driven overhead feed rollers follow the wood contour

- Servo-controlled saw stroke as standard

- VarioStroke sawing unit optionally available

- Integrated high-performance waste gate as standard

- VarioSpeed infeed belt as standard

- Min. fixed length behind saw blade: 110 mm (also at the board end)

- Cutting tolerance ± 0.8 mm to 1000 mm length

| Working height | 900 mm |

| Min. cutting tolerance up to 1 m fixed length | +/- 0.8 mm |

| Max. cutting tolerance up to 2.5 m fixed length | +/- 1.5 mm |

| Thickness tolerance | +/- 3 mm |

| Min. fixed length behind saw | 110 mm |

| Max. feed speed | 300 m/min |

| Max. acceleration | 50 m/s2 |

| Electrical connected load | approx. 18 kW |

| Air consumption | approx. 1200 Nl/min |

| Operating pressure | approx. 8 bars |

| Extraction speed | approx. 30 m/s |