- Главная

- Категории

- Деревообработка

- Cutting / Gluing

- OptiCut 260

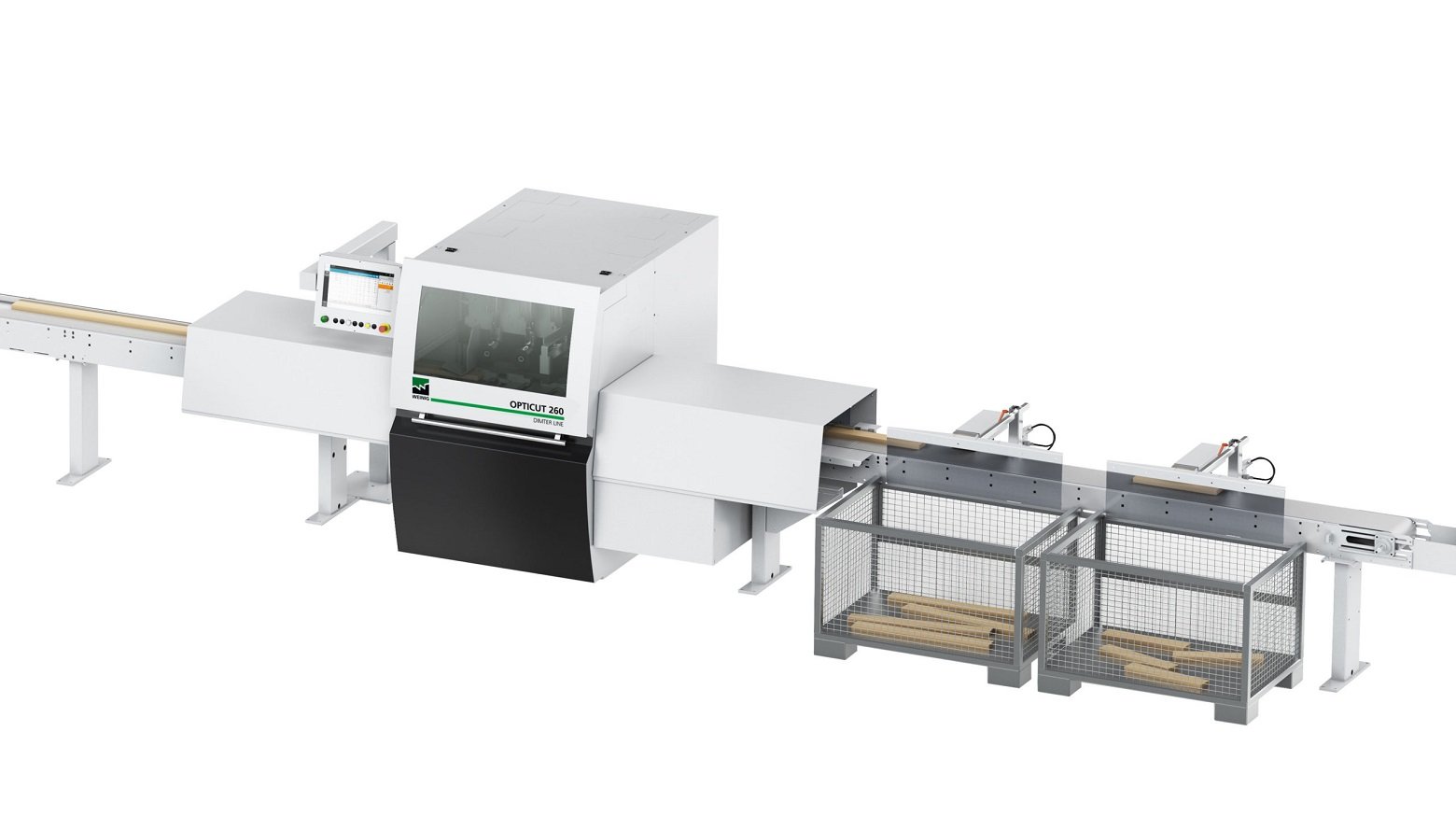

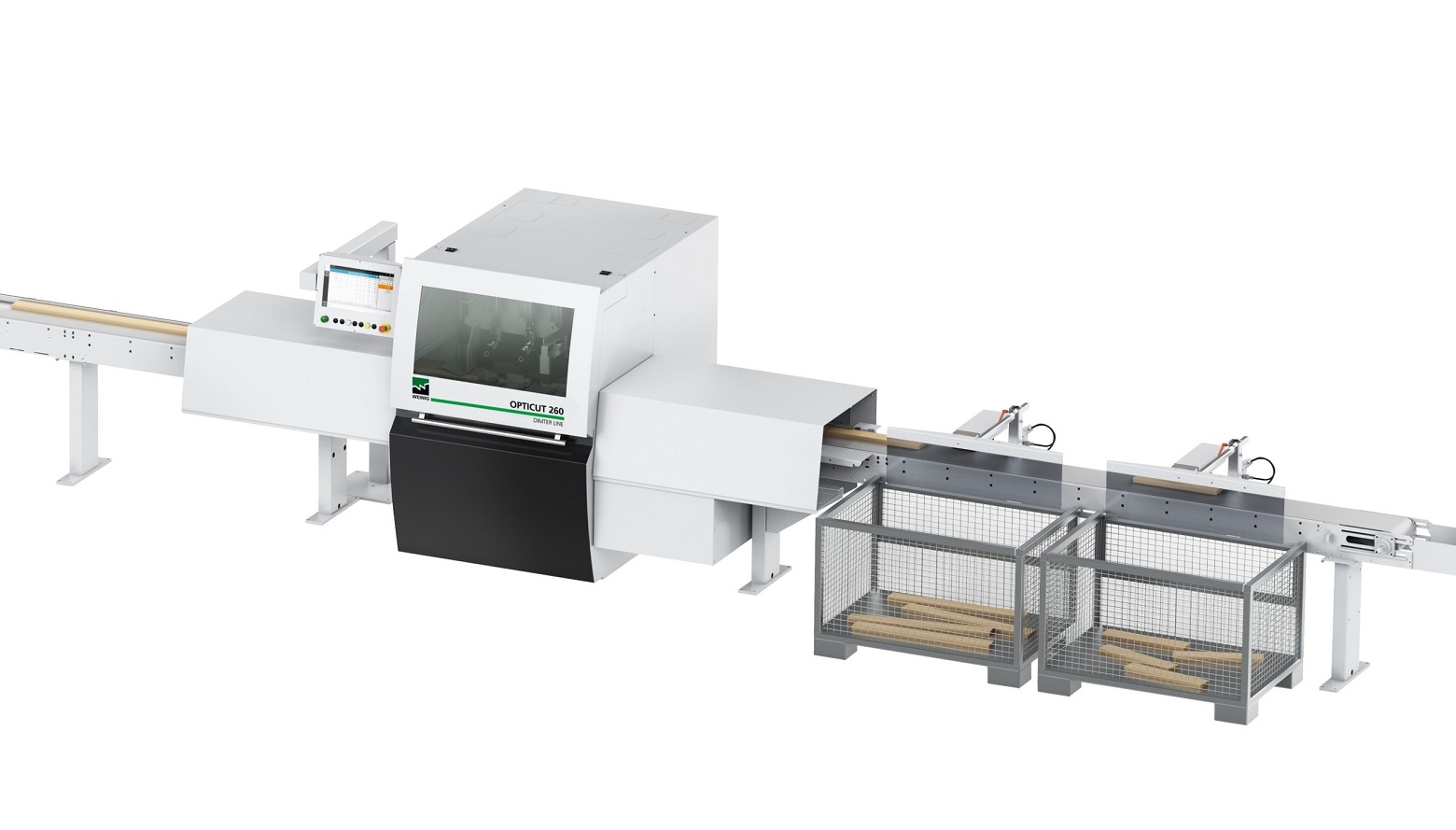

WEINIG

OptiCut 260

Available for difficult and lower grade wood

High performance without compromising on standards is the advantage that the OptiCut 260 offers you. Independently-driven measuring wheels only measure when the wood is in motion. Uncontrollable slippage or belt elongation in the infeed system do not distort the cutting results as the machine cuts at precisely the intended point. This avoids errors with good quality wood and guarantees precise fixed lengths regardless of the wood quality. Standard conveyor belts reduce the operating costs of the machines, which are profitable all-round.

Our optimizing cross-cut saws offer high performance potential in every respect. To maximize this potential, the intelligently controlled VarioSpeed, among other things, reduces the spacing between consecutive workpieces as much as possible. The OptiCut thus provides a continuous supply or workpieces, so that the idle time of the machine is minimized. This increases the efficiency and productivity of the optimizing cross-cut saw.

The WEINIG OptiCut 260 provides

- VarioSpeed infeed belt as standard

- 5 driven feed rollers from below, pressure rollers from above

- Pneumatic saw stroke

- Cutting of cross-sections up to 260 x 12 mm or 160 x 80 mm is possible

- Saw blade diameter 500 mm

- Integrated waste gate as an option

- Measuring wheel in front of saw blade

- Min. fixed length behind saw blade: 140 mm

- Cutting tolerance ± 0.8 mm to 1000 mm length

| Standard | Option | |

| Saw motor performance | 7,5 kW | |

| Saw blade Ø | 500 mm | 520 / 550 mm |

| Saw blade bore | 30 mm | |

| Min. cut height | 12 mm | 3 mm |

| Max. cut height | 80 mm | 100 mm |

| Min. cut width | 30 mm | 30 mm |

| Max. cut width | 260 mm | 250 mm / 300 mm |

| Min. incoming length | 400 mm | |

| Max. incoming length | 6300 mm | |

| Min. nominal cross-section | 30 x 12 mm | 30 x 3 mm |