- Главная

- Категории

- Деревообработка

- CNC Machines

- DYNESTIC 7535

HOLZER

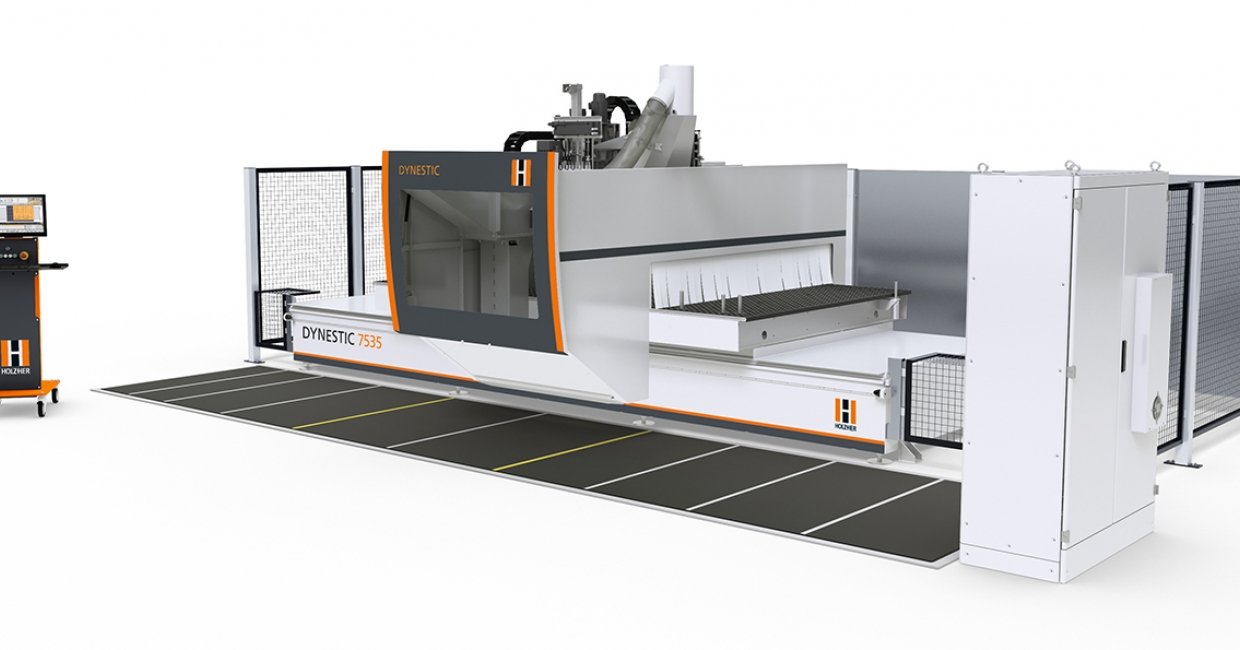

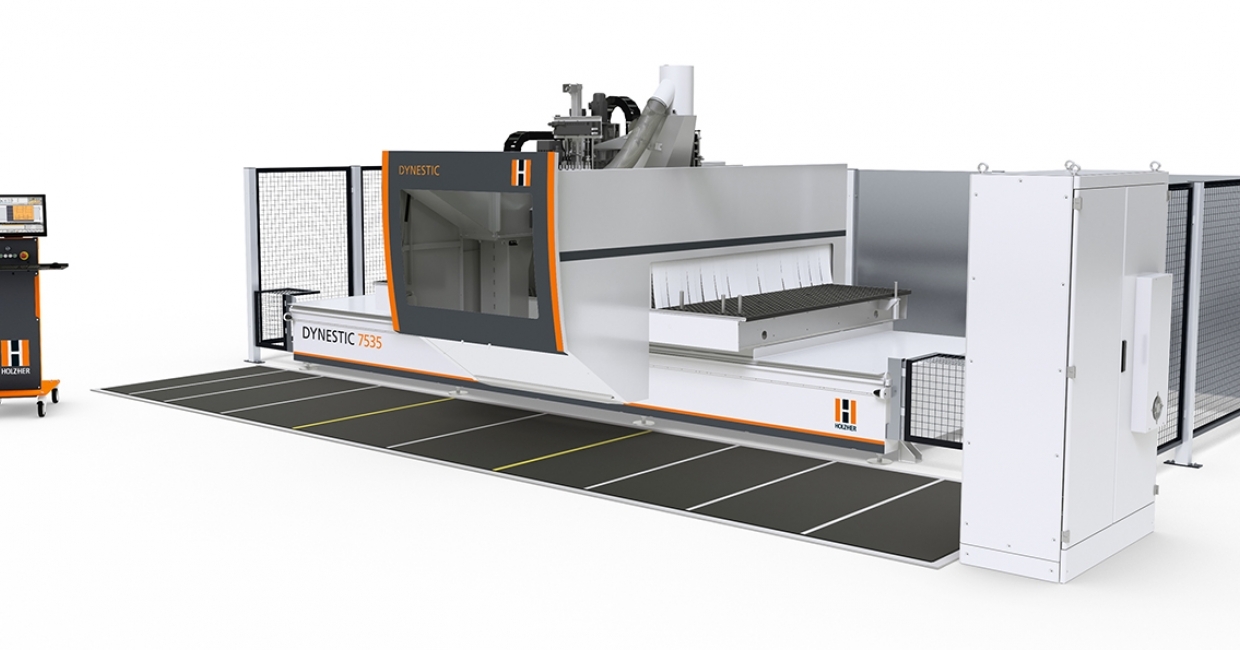

DYNESTIC 7535

CNC machining center

The DYNESTIC 7535 CNC with 5-axis cutting spindle and a 2,200 mm deep grid table is the flagship of the new series with nesting machines made by HOLZ-HER. Even with this huge working depth, the moving stands in solid gantry design ensure utmost precision and optimum cutting results via two synchro drives.

The DYNESTIC 7535 is equipped with the completely newly developed CAMPUS software package version 7. The functionality and nesting result of the optional BetterNest software are really impressive. The high-flow nesting table ensures optimum vacuum flow and can also be supplied with an intelligent 16-field grid table and software-controlled vacuum control. Double-acting suction pads enable the clamping of doors, staircase components, etc., making this 5-axis CNC machine a real all-rounder with virtually unlimited machining options.

The DYNESTIC 7535 makes it possible to process lengths greater than 6 meters. The liquid-cooled 5-axis precision cutting spindle is already supplied as standard with 10 kW power and a speed range of 1,000 – 24,000 rpm on all HOLZ-HER 5-axis machining centers. The high-performance 12 kW cutting spindle or the 17 kW PRO-TORQUE spindle with controlled axis locking is available as an option.

Whether as a DYNESTIC 7535 classic, push, automatic or lift – this 5-axis CNC machine sets standards!

Here is what the HOLZ-HER DYNESTIC series offers

- CAMPUS Machine Control

- High-Flow Nesting Table

- 10 Year Guarantee on All Linear Guides

High Performance Nesting Table

Nesting technology for sustainable production. In Nesting technology, a porous wear plate (usually a thin MDF board) is vacuumed against the machine table. It works as a kind of "flat suction cup" for stacking workpieces. Thanks to Nesting technology, optimized processing and cutting of sheet and board materials is possible.

For size cutting according to the prepared cutting patterns on the Nesting table.

Machining parts on hand-placed vacuum cups.

The small pitch of the HOLZ-HER Nesting table elements of only 50 mm guarantees good vacuum distribution over the entire table area.

As an option, and depending on the configuration of the machine, you can choose a console with a mobile stand. Casters on the stand allow you to place the console exactly where it is most convenient in terms of workflow.

Thanks to various options, the DYNESTIC models are ideal for processing a wide variety of materials. Working with sensitive and heavy materials is facilitated by the air cushion. The ColdGun option is particularly well suited for plastics, aluminum and composite materials. Thanks to her, the parts and the cutter always remain cold. This option therefore guarantees an extremely long tool life. Below is a list of some of the materials that can be processed on DYNESTIC machines.

- Plexiglass

- Plastic

- Acrylic stone

- Composite aluminum materials

- Aluminum Core Materials

- Aluminum profiles

- Board wood materials

- MDF boards

- Glued solid wood boards

The cardan machining head with a power of up to 18 kW (standard: 13 kW) allows precise production of complex arcuate or curved parts, for example, for flights of stairs of furniture and building elements with complex designs. The compact and powerful full interpolation machining head runs up to 24,000 rpm and can withstand very high loads thanks to ceramic bearings and liquid cooling.

The optional 18kW spindle (S6) features the PRO-TORQUE technology, which, thanks to the automatic mechanical locking of the A and C axes, makes it possible to obtain very high torque on the spindle. Optimum chip suction is ensured by the possibility of positioning the suction hood in eight positions.